3D printing in Medicine

3D printing has without a doubt altered the designing scene, and the restorative business is on the front line of probably the most inventive applications to date. The innovation has demonstrated itself a hearty and flexible one, as more organizations are utilizing it toward creating novel gadgets. Be that as it may, not at all like in different businesses, the innovation has yet to achieve a genuine toehold in medtech. Since 3D printing is still generally new, it has yet to go through the motions that any new innovation must. Thus, quite a bit of 3D printing’s establishment as of now lies in the scholarly and trial domain.

Prosthetics and Casts

One of these industry shakers is the Osteoid, developed by Turkish mechanical creator Deniz Karasahin. The Osteoid is at last a 3D-printed cast that fuses a low power beat ultrasound (LIPUS), advancing bone crack mending in non-union breaks. „The inventor of the Osteoid is situating the gadget, once snared to ultrasound for 20 minutes a day, to help decrease the time it takes for the harm to mend by about 40 percent,“ says Alex Chausovsky, Principal Analyst at IHS Technology. „Numerous a great many individuals endure broken bones consistently, and this would not just accelerate the recuperating time of those wounds, additionally fundamentally bring down the expense of treating making clients more agreeable,“ finishes up Chausovsky“Project Daniel“ includes the organization Not Impossible Labs setting out to Sudan to make 3D-printed prosthetics for youngsters who have lost appendages because of the war. A standout amongst the most endearing late employments of 3D printing is „Venture Daniel,“ in which an organization called Not Impossible Labs is delivering ease prosthetic appendages in Sudan for casualties attacked by war. The organization has done as such by utilizing just shopper review 3D printers, making the prosthetic gadgets financially savvy at a minor $100 per appendage and delivering them in less than six hours. Despite the fact that his likewise implies the level of exactness is restricted, it is a begin, demonstrating the boundless openness of 3D printing.

Implants

Likely the most longing 3D-printed endeavors are starting now being implanted in patients. Hasselt University in Belgium has used 3D printing as a piece of making a jaw embed from Xiloc. The supplement was secured with a hydroxy-apatite bone compound and especially planned for the patient. The framework demonstrated superb results, setting the bar for future techniques of its kind. Another noteworthy usage of 3D printing for additions was done in a framework by the University Medical Center of Utrecht in the Netherlands in which experts used an absolutely 3D-printed install in supplanting a woman’s skull. Stood out from old schedules that used a kind of security, this new method considers a predominant fit and patient specificity.

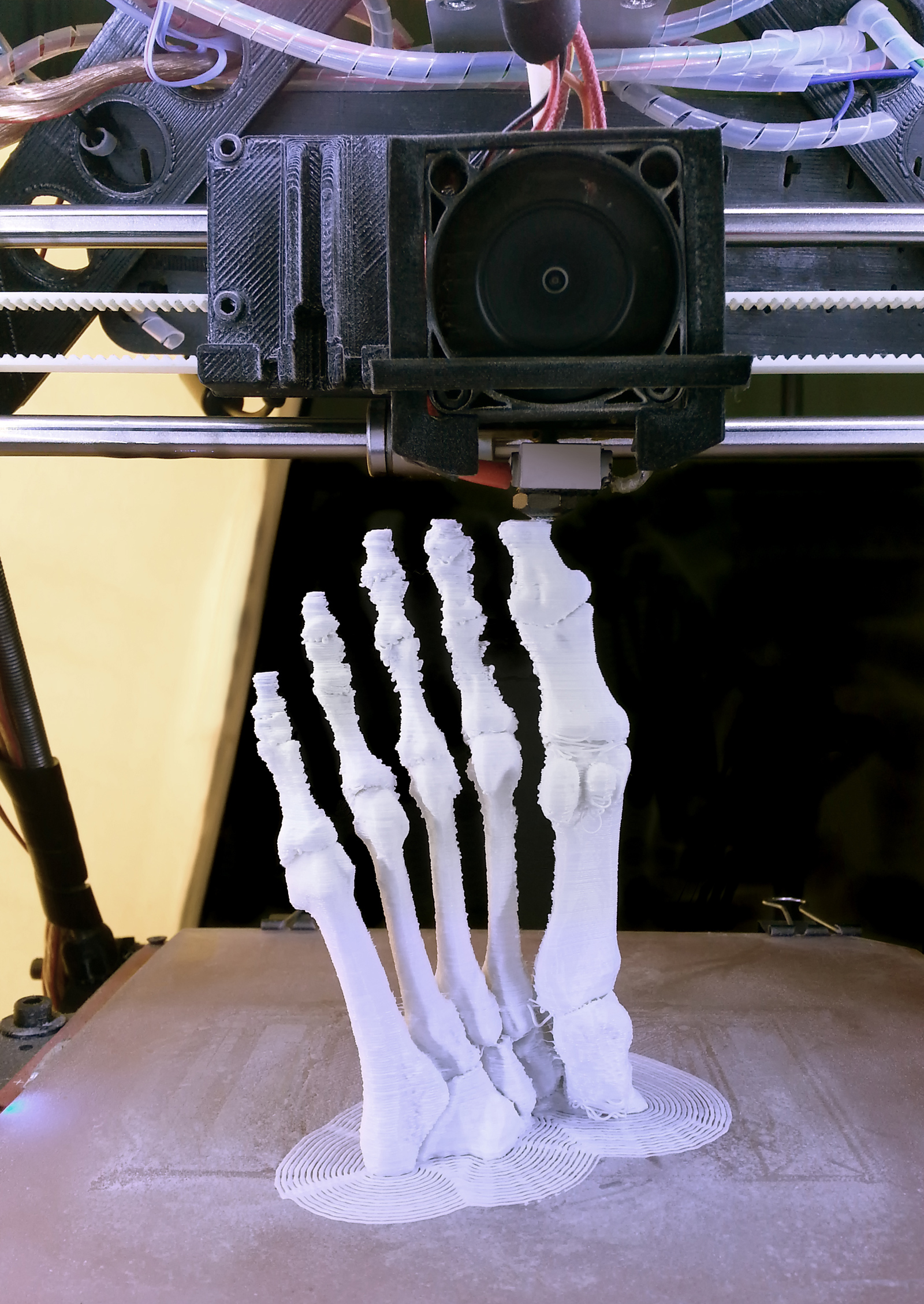

Produced Tissues

OxSyBio is in a matter of seconds exploring 3D printing for making fabricated tissues, through the use of a framework became by Gabriel Villar, an expert at Cambridge Consultants. The development is significantly advanced, as the material incorporates the usage of little water dabs held together by small motion pictures that duplicate cell movies. Certain proteins can even be used that allow the dabs to pass on among each other comparably that cells bestow in living tissue. „This development may be created to make on-interest swaps for living tissue,“ says Villar. „Since it is possible to control the substance of each dab in the printed material, the geometry and exploration of the material can be specially designed for each circumstance. A more drawn out term goal is to print an utilitarian substitution for an entire organ.“

Analysts at Oxford Performance Material in Connecticut have made a 3-D printed cranial prosthesis intended to supplant lost bone in the skull. As of late, one of these inserts was utilized to recreate a skull desert in a patient in the United States. Lawrence Bonassar, PhD, at the Cornell University Department of Biomedical Engineering as of late utilized 3-D printers to make a human ear cartilage. A gathering drove by Anthony Atala, MD, has effectively embedded mouse dermal skin unions imprinted on 3-D printers into host beneficiaries. Washington State University brags a Materials Research Group that is pushing the limits of 3-D printing by making bioceramic composites and custom titanium inserts for burden bearing purposes. What’s more, a Massachusetts Institute of Technology gathering is presently making manufactured bone-like materials with 3-D structures that are a great deal more steady with those found in nature than different past man-made materials. As indicated by their gathering, „the conceivable outcomes are unfathomable.“

No biologic inserts have been set into people as of right now. On the other hand, one can envision that this may not be far away.

There are no comments published yet.